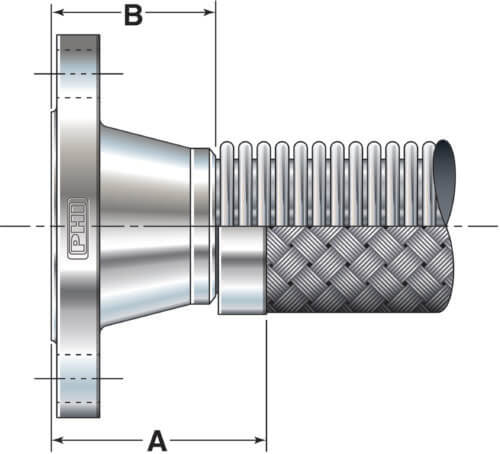

Raised face weld neck (RFWN) flanges are one of the most commonly used flange types in the piping industry. They are easy to recognize with their tapered hub that is matched to the wall thickness (bore) of the pipe. The flange bore is machined to match the ID of the pipe or fitting. This creates a smooth transition to and from the weld neck flange and prevents turbulence at the welding neck.

Weld neck flanges are engineered to provide reinforcement in applications requiring high pressure. The flange provides column strength as well as provides excellent stress distribution through the tapered neck. It also helps in low cycle fatigue caused by line expansion or other variable forces.

Welded Neck Flange: Stainless Steel / Carbon Steel

| HOSE SIZE |

1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| A | 2.50 | 2.81 | 2.93 | 3.00 | 3.19 | 3.25 | 3.75 | 3.75 | 4.00 | 4.50 | 4.50 | 5.00 | 5.00 | 5.50 |

| B | 1.88 | 2.06 | 2.19 | 2.25 | 2.44 | 2.50 | 2.75 | 2.75 | 3.00 | 3.50 | 3.50 | 4.00 | 4.00 | 4.50 |