Precision Hose & Expansion Joints has the proven capability of fabricating intricate and highly sophisticated assemblies to satisfy the needs of our customers. A sampling of these quality assured assemblies are as follows:

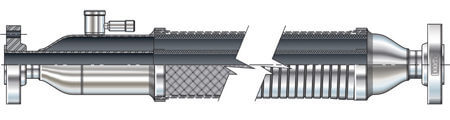

JACKETED ASSEMBLY

Jacketed assemblies are normally used in one of the following applications:

- As a heated transfer line for those products, such as Sulphur, which must be maintained at an elevated temperature in order to flow readily. Steam or hot oil is circulated through the jacket, which in turn heats the product being conveyed in the core hose.

- As a cryogenic transfer line, maintaining a high vacuum in the jacket effectively insulates cryogenic liquids being conveyed in the core hose.

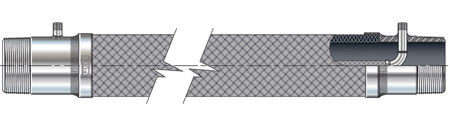

TRACED ASSEMBLY

Traced Hose assemblies are used:

When the product being conveyed must be heated in order to flow freely. Steam or hot oil circulated through the inner tracer hose heats the product in order to maintain flow rates.

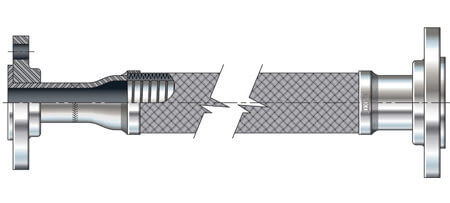

LINED ASSEMBLY

Lined hose assemblies are used:

When high flow rate of the conveyed product could cause resonant vibration in an unlined corrugated metal hose.

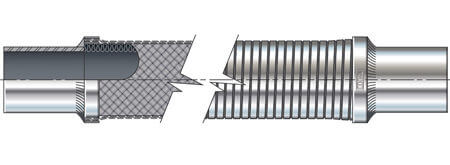

GUARDED ASSEMBLY

Guarded assemblies are used:

Where a corrugated metal hose could be damaged by rough handling, abrasion, or over-bending.